Luer Lock Lubricator

Perinski

PerinskiFebruary 13, 2025

Description

Luer Lock Accessories for Lubrication and Maintenance of 3D Printers

--------------------------------------------------------------------

In this publication, I paid more attention not to the accessories themselves but rather to the issues of 3D printer maintenance and the specifics of printing with PETG. However, this does not diminish the significance of the accessories: little has been said about them because, once in your hands, they speak for themselves. You only need to try them once to understand their convenience and efficiency.

Maintaining mechanical parts exposed to friction is a key aspect of ensuring the stable operation of any equipment, especially a 3D printer. During operation, 3D printers experience significant loads due to friction on linear shafts and lead screws, as well as exposure to high temperatures. Neglecting proper care of these components can lead to a deterioration in print quality, increased noise levels, and a shorter lifespan for the device.

The importance of proper lubrication cannot be overstated. It reduces friction, prevents wear on components, and protects them from corrosion. For 3D printers, special lubricants are recommended that are designed to work under high temperatures and heavy loads. For example, BambuLab offers its range of materials that excel at maintaining the moving parts of a printer. However, alternative solutions are also available on the market, such as products from the SuperLube brand. These lubricants feature a synthetic base with added Teflon (PTFE), providing a low coefficient of friction and resistance to extreme temperatures. This makes them particularly useful for tasks requiring long-term stability and wear protection.

SuperLube lubricants stand out for their high quality and versatility. For linear shafts and lead screws, the following are especially suitable:

* **SuperLube Multi-Purpose Synthetic Grease**– A multi-purpose synthetic grease that provides excellent protection against wear and corrosion. Key properties: resistant to high temperatures, moisture-proof, with added PTFE micro-particles.

* **SuperLube Synthetic Lightweight Oil**– A lightweight synthetic oil ideal for lubricating linear guides. Key properties: minimizes friction, prevents wear, and contains PTFE for enhanced performance.

The SuperLube company produces a wide range of lubricants, so it is recommended to carefully study their assortment before making a choice — you may find even more suitable options for your tasks. Additionally, many other manufacturers produce high-quality lubricants, though I am less familiar with their products.

Using high-quality lubricants not only extends the lifespan of a 3D printer but also ensures stable print quality, reducing the likelihood of breakdowns.

It’s worth noting that this material applies to printers with linear shafts, such as the BambuLab X1C. For printers using HiWin-type rails, different lubricants are required, not those mentioned above. Additionally, as a precaution, I’ll mention (though I’m sure you already know) that the BambuLab X1C has carbon fiber shafts along the X-axis. These should never be lubricated with lubricants. Instead, they should be periodically wiped with a lint-free cloth and alcohol to avoid damage.

### Advantages of Using Dispensers

A 3D printer is a fairly complex device, and accessing its mechanical parts is not always convenient. Lubricating them manually, for example, with a brush, can be not only inconvenient but also inefficient. Previously, I developed a range of dispensers for syringes with a Luer lock connection in volumes of 3, 5, and 10 cubic centimeters. Among them are both mechanical and electric models, although I most often use the electric dispenser in my work due to its convenience and functionality. Nevertheless, the mechanical dispenser is also always on hand and actively used.

Originally, the dispensers were created for use in electronics, particularly for dispensing solder paste and flux. However, they are perfectly suited for lubricating various components and parts. Links to dispenser projects available for download allow you to choose the most suitable model:

* [Electric Dispenser 5cc](https://makerworld.com/en/models/549884)

* [Mechanical Dispenser 3cc](https://makerworld.com/en/models/122976)

* [Mechanical Dispenser 5cc](https://makerworld.com/en/models/549883)

* [Mechanical Dispenser 10cc](https://www.thingiverse.com/thing:3148234)

* [Dispenser Magnetic Cap](https://www.thingiverse.com/thing:5142525)

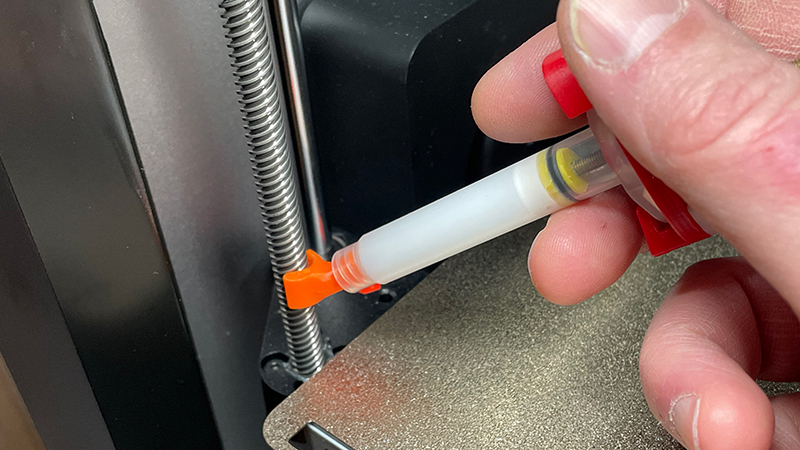

As for the accessories for which this publication was created, they are compatible with any dispenser. For example, for lubricating lead screws, a nozzle was developed that replicates the trapezoidal thread of the screw with a gap. This allows lubrication to be evenly distributed over the teeth, thread edges, and inside. By turning the screw, you can ensure even application of the lubricant.

For linear shafts, a nozzle with a groove is also provided, through which lubrication is distributed over the entire surface of the shaft. When using this nozzle with liquid lubricant, it is additionally recommended to use a lint-free pad or spacer between the shaft and the nozzle to prevent the oil from spreading and dripping. Additionally, an adapter was developed for transferring lubricant material from one syringe to another, as well as a protective cap with a Luer lock connection.

### About PETG and Its Properties

As for printing this project, I used PETG. Why PETG? This material is inert to various lubricants, fluxes, and other chemicals. This is especially important to ensure that the plastic does not degrade, especially when using petroleum-based lubricants. However, in the context of 3D printers, we are dealing with chemicals that are not used here, making PETG even more suitable.

Many users love this material for its strength and reliability. Others complain about its brittleness or tendency to crystallize. Such issues can arise from improper storage or handling. PETG is hygroscopic and absorbs moisture, which degrades its printing properties. Therefore, it is important to store it in a dry place, in airtight bags with desiccant.

Before printing, it is recommended to dry the plastic in specialized drying chambers or in the printer using a heated bed. For example, for PETG, drying at a temperature of about 65 °C for 4–6 hours is recommended. These parameters help avoid problems associated with moisture, such as bubbles or poor surface quality.

I have fine-tuned the printing parameters for PETG to ensure strong prints with excellent layer adhesion and high-quality surfaces. You wouldn’t believe how many trials and errors I went through before achieving high-quality parts. The models were repeatedly reworked, reprinted, and adjusted until they finally became perfect. If you’re interested, you can [download the files in 3MF format](https://makerworld.com/en/models/1105221) to see my settings and perhaps use this profile for printing. These settings include experiments with variable layer height to optimize the printing of complex parts. For example, finer layers were used for the Luer lock threads, which smoothly transitioned to coarser layers in other parts of the object.

It is important to remember not to overheat PETG, especially when printing small parts. The optimal temperature for printing PETG is 220–250 °C, depending on the manufacturer and printer settings. Overheating can lead to molecular degradation, making the material brittle and fragile. Following proper technological processes makes PETG a universal and high-quality material, particularly suitable for working with chemicals and lubricants.

### A New Life for Dispensers with Accessories

With these accessories, the dispensers have gained new life and meaning. The models were designed based on ISO standard drawings for syringe nozzle channels, with allowances for plastic shrinkage. Therefore, if you use other types of plastic, take this into account and adjust your slicer settings. Lubrication has become so convenient and effective that you’ll want to keep lubricating, but it’s important to know when and what to lubricate. In particular, the printer I mentioned will remind you when it’s time for maintenance based on the number of hours worked.

### Conclusion

I hope the accessories I created will help you in maintaining your 3D printers. May they become a part of your workflow, simplifying routine tasks and making them more convenient and efficient.

### Parts links below:

* [ESUN Filament PETG](https://go.like-it.link/kGjrW)

* [Industrial Syringe 3CC 5CC 10CC 30CC 50CC](https://go.like-it.link/QWDD1)

* [Super Lube Multi-Purpose Synthetic Grease with Syncolon 21030](https://go.like-it.link/vq5L6i)

* [Super Lube Multi-Use Synthetic Lightweight Oil 52004](https://go.like-it.link/6CkIs5)

### Links to used tools:

* [NOGA deburring tool and Blades](https://go.like-it.link/h5jhx)

### My favorites:

[](https://like-it.link/favorites)

#### Thank you for every tip or donation,

it means great recognition for me and helps a lot to keep going!

[](https://www.paypal.me/perinski)

[https://ko-fi.com/perinski](https://ko-fi.com/perinski)

**BTC:**bc1qplpzq36ghw84hty4nn2zzu4ps4sdh4th0v93j8

**ETH:**0xc766ebbeAa76aaf629788c8F99C33A8d80d48977

### My some other things:

[](https://like-it.link/thingiverse)